100 % Recycling for people & nature

Tectan® is made out of 100 % secondary raw materials from the beverage carton industry. In a specially developed process, the waste is shredded, dried and then converted into granules.

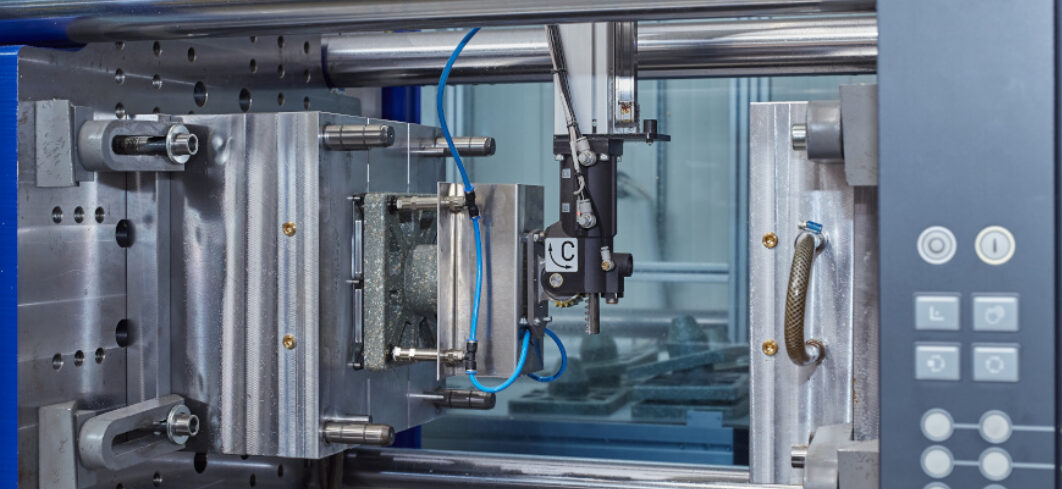

By using state-of-the-art injection-moulding technology we guarantee a high-quality and sustainable manufacturing of our Tectan® products.

The production in Diez

Tectan® is made from the residues of the beverage carton industry, consisting largely of paper. These residues (raw materials) are shredded, dried, and processed into granules in a specially developed process.

The production in Diez

Paper and polyethylene together create the dimensionally stable material Tectan®, which makes our core plugs even more durable. This makes them ideal for stabilizing winding cores during transport.

The production in Diez

About Entwicklungsgesellschaft für Verbundmaterial Diez (EVD)

The EVD mbh was founded in 1990 by the Tetra Pak Group to produce secondary products from coated cardboard waste. The resulting material, Tectan®, is used for the production of sleeve plugs and edge protectors, which play an important role in transport security. Modern high-performance machines ensure a high level of process reliability. The resulting quality is reflected in the satisfaction of our steadily growing customer base.

With the support of funds from the European Regional Development Fund (ERDF) and the state of Rhineland-Palatinate, we are investing in a new injection moulding machine to increase energy and resource efficiency. The objective is to achieve an increase of at least 20% in energy efficiency and to save at least 40 tonnes of CO2 compared to the old plant technology.